Step By Step rebuild of Jabsco bronze seawater cooling pump.

Update 3/12/21 (Click Here)

The Jabsco seawater pump is widely used by boat manufacturers for engine cooling systems. These are reliable pumps but will fail at some point.

There are two reasons a pump will fail. The most frequent problem is impeller failure. The other common problem is a shaft seal failure leading to bearing damage.

If your pump is not pumping water and is not leaking you simply have an impeller failure. If your pump is pumping water and you see it leaking you have a seal failure.

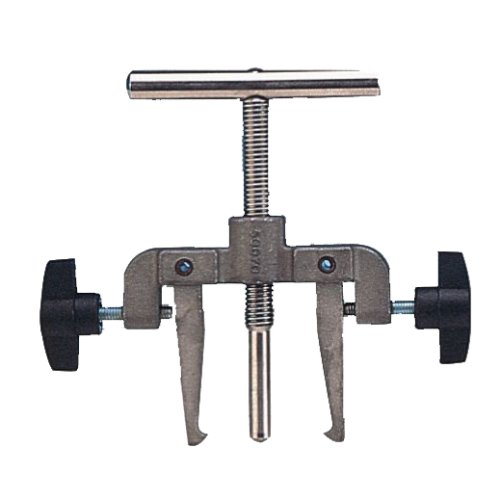

Impeller failure is pretty easy to correct. Getting the old impeller out can be tough without an impeller puller. It’s a pricey little special tool. Chances are you won’t need it.

A more difficult problem is a shaft seal failure. Shaft seals keep water from the bearings. Salt water will quickly destroy the shaft bearings.

If you notice any water leaking from your seawater cooling pump the shaft seal is bad and it won’t be long before bearing failure.

Jabsco Pump 43210 Impeller Replacement

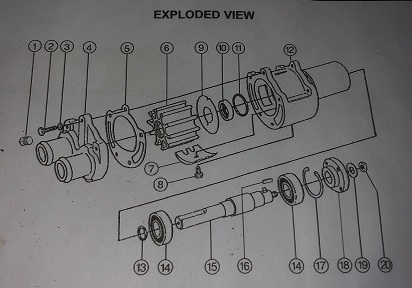

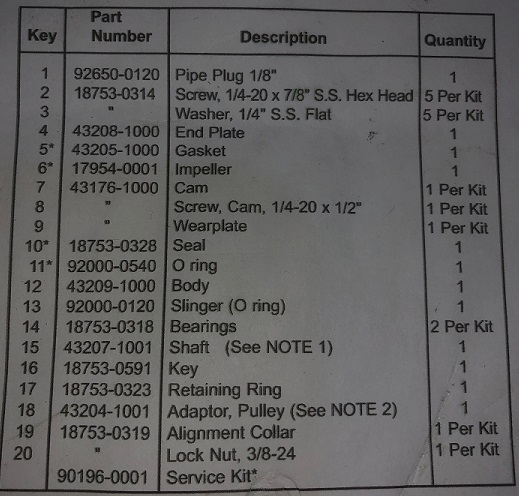

Start by removing the end cap (part #4 shown below) exposing the pump impeller. Remove the impeller. At this point, if there is no seawater leaking through the seals and the bearings (2) roll smoothly and are tight, all you need to do is install a new impeller, gasket and re-install the end cap. Your pump is ready to go.

If the seals have been leaking or the bearings are not operating smoothly you’ll have to completely dismantle the rest of the pump.

Jabsco Pump 43210 Overhaul

If your seals failed and sea water leaked through to the bearings then it’s time to overhaul the pump. This includes replacing the seals and damaged bearings. Some special tools, complete disassembly and a thorough cleaning are required.

You can do it all yourself. Or, for about $100 (which is what I was quoted) you can have a machine shop do it for you (not including parts). If you don’t have the tools you will spend about the same amount buying the tools as if you had it done by a shop.

I elected to do it myself. I wanted to understand what was required to rebuild one of these pumps and I wanted to have what I needed on hand to be able to make repairs if I was not sitting at home with a machine shop close by.

The most important tool needed is one for pulling the bearings from the shaft and then pressing new ones onto the shaft. The machine shop simply uses a press. To perform this function I used a wheel puller with a bearing separator. It was a bit awkward but it works.

Click here to see exactly how I put together my own low cost press.

The problem you’ll have with this set up is that the length of the pump exceeds the length of the wheel puller’s range. I solved the problem by buying threaded bar stock and cut arms to the needed length.

With these tools I was able to remove the shaft from the pump housing, the bearings from the shaft and then replace them all.

Cleaning Up The Jabsco Pump 43210

There are few products available that will remove the crud built up inside the pump housing from the sea water. You can scratch and scrape to your hearts content. Or, you can dip the whole thing into a bucket of muriatic acid solution.

Hydrochloric acid or muriatic acid is commonly used in swimming pools to help balance the ph levels. It is commonly available and very reasonably priced. I used a 10 to 1 solution and dunked the parts for about an hour.

-

Jabsco Pump 43210 -

Jabsco Pump 43210-0001 -

Jabsco Pump 43210-0001

It’s amazing how effective this cleaning solution is. The parts all look like new. Just remember to rinse thoroughly or the acid will continue to work.

Sourcing Parts For The Jabsco Pump 43210

This was probably the most time consuming part of the project. The impeller was readily available at my local marine supply store. The bearings were a little harder to find. I contacted a local industrial bearing and seal supplier and had the bearings and seal in a couple days.

It’s possible to buy a complete rebuild kit. Unfortunately, these kits are very pricey. Bearings are billed at about $40 each and the shaft seal is about the same. I found the parts to be far cheaper from the industrial suppliers.

For example, the bearings cost a little over $8 each and the seal was less than $15. The impeller has to come from Jabsco and runs about $40. I should mention that the impeller comes with a new gasket and special lubricant to prevent damaging the impeller on the initial start up.

The last challenge was to find the right size O-rings (there are two). I was lucky to have a really good hardware store nearby with a complete selection of O-rings. They cost less than $5 for both. Just be sure you find the correct diameter and thickness.

Completing the Jabsco Pump 43210

Final assembly of the pump is straight forward. Use the same tools you used to remove the bearings for pressing the new bearings onto the shaft and the shaft into the housing.

Use the exploded pump diagram above as a guide for assembly. The whole project took a few days and cost less than $200, including tools. Retail cost of this particular pump ranges from $360 to $900 with most vendors charging about $600.

I would say Skill level for the Jabsco Pump 43210 rebuild is moderate. If you are dealing with just one pump you might want to shop around for the lowest priced ($360) new pump and be done with it. I have two engines and two pumps and being able to service them myself will save hundreds of dollars over the years.

Leave a message here if you are interested in sourcing bearings and seals.